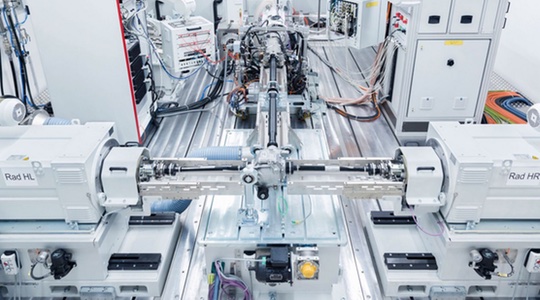

Engine development and validation laboratory

Check the reliability of high-load components (such as pistons, connecting rods, crankshafts, etc.), as well

as the durability of bearings, piston rings, valve train wear, and oil consumption.

Include: start test, idle test, power test, load characteristic test, mechanical loss power test, work uniformity

test of each cylinder, oil consumption test。