With the rapid development of science and technology, the market puts forward higher requirements on the safety, comfort and environmental protection of automobiles. Therefore, the excellence of the manufacturing process can keep up with the needs of the times. Shanghai Hongbin is an experienced quality field. Experts can provide you with a complete vehicle inspection program for various auto parts and automotive materials, which will protect your R&D and manufacturing.

Repair area for stamping parts with explosion-proof is set up to ensure the product quality of aluminum stampings and to control the mold's technical status, resulting in different degrees of scratches, cracks, bulges, wrinkles, and draw indentations on the stamping surface due to various reasons

welding laboratory is set up for approval of strength and quality for in-house welding parts assembly at project phase, and monitoring of strength and quality at the mass production phase

Coating quality control: The quality of the coating film is performed in terms of mechanical properties (such as adhesion, flexibility, impact strength, hardness, gloss, etc.) and special properties (such as fire resistance, acid resistance, oil resistance, etc.) with protective functions. So as to meet the development needs of coating materials R&D laboratory materials

Final assembly quality control: To achieve quality control including assembly inspection of UPS, roller test bench, toe-in adjustment, brake detection, gap and flush measurement, road test, vehicle seal test.

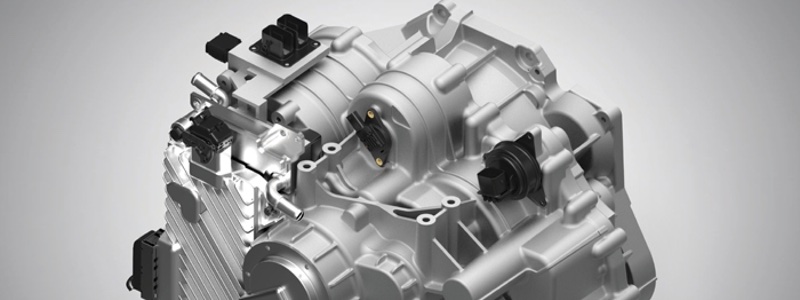

To meet the production requirements of the powertrain system, a comprehensive quality assurance system and testing center must be established. It is required to have the ability to detect all sizes of assemblies and components, material analysis capabilities, and chemical analysis capabilities of key and important non-metallic materials. Security, consistency, traceability, etc.